Dendoman Electric Jaw Crusher

Step into the future of crushing with the Nakayama Dendoman 10t Electric Crusher, exclusively available from Earth Equipment Ltd and Vastuss. Embrace eco-smart solutions as this electric crusher offers a greener and sustainable alternative to traditional diesel-powered machines.

Dendoman Electric Jaw Crusher

Crushing the Future: Dendoman 10t Electric Crusher – Embrace Sustainability!

Welcome to Earth Equipment Ltd, your go-to source for the Nakayama Dendoman electric 10t jaw crusher – a game-changer in the world of crushing and recycling. As a leading supplier of environmental solutions, we are proud to offer the Nakayama Dendoman jaw crusher, a powerful and eco-friendly solution for crushing various materials. Whether you’re dealing with construction debris, concrete, or quarry aggregates, the Dendoman jaw crusher delivers outstanding performance and efficiency.

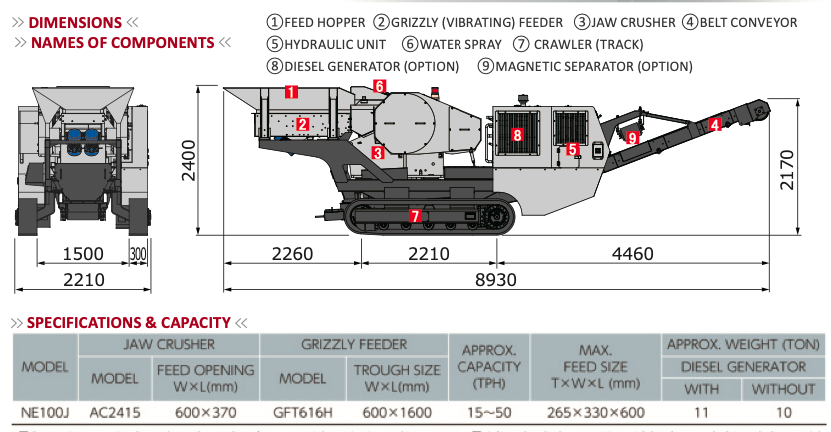

The Nakayama Dendoman electric 10t jaw crusher is designed with cutting-edge technology and innovation. Powered by electricity, it minimizes carbon emissions, making it a sustainable choice for environmentally conscious projects. The crusher’s compact design and lightweight construction ensure easy transport and maneuverability, ideal for on-site crushing applications.

At Earth Equipment, we prioritize versatility and convenience for our customers. The Nakayama Dendoman jaw crusher offers adjustable settings, allowing you to achieve the desired crushed material size for different projects. Its high-capacity jaw ensures efficient and rapid crushing, enhancing overall productivity.

Experience the power and performance of the Nakayama Dendoman electric 10t jaw crusher. Partner with Earth Equipment Ltd to revolutionize your crushing and recycling operations. Contact us today or why not speak to Eugene Donnelly from Vastuss to explore the features of the Nakayama Dendoman and discover how our jaw crusher can elevate your crushing endeavors to new heights of efficiency and sustainability.

How it Works

The Dendoman Electric Jaw Crusher has a small incorporated diesel engine for use when tracking on site. Once in position, the engine is turned off and the unit is plugged into either 3 phase mains or a site generator. All operations to do with crushing are electrically driven. It is generally accepted that uptime with electric power is 10% higher than diesel alternatives, thus producing a more efficient means of crushing. (Please note the 10t crusher has the option of having batteries, which negate the diesel engine completely, and bring down the power required to run this unit exponentially. On board batteries have the capacity to offer 4 hours continuous crushing unplugged)

Emission laws are only getting stricter, currently within London a machine has to have a tier 5 engine to be allowed to work, utilising an electric operated machine will be an investment for the future allowing industry to continue working while protecting the environment.

Benefits of Electric over Hydraulic

- Electric Motors are more efficient at producing torque

- Electric motors last longer than their hydraulic counterpart

- Less maintenance with Electric motors and switchgear

- depending upon machine application, hydraulic oil can be required to be changed every 500 hours

- Hydraulic filters every 250hrs

- Electrical controls to control solenoids for hydraulic operations is often bulky and clumsy, meaning that hydraulic pipes and connections are sometimes in very tight conditions. (Leaks and damaged pipes can be left to weep rather than strip down to repair)

- Electrical controls situated under hydraulic filters and pipes etc can become damaged from leaks which cause dead shorts.

- When repairing hydraulic motors or hoses, it is often almost impossible to contain leaked oil.

- With the range of hydraulic fittings it is very hard to have the correct fittings to make repairs at hand.

- Electrical controls with motors is a very clean system, repairs are a lot easier, cable and wiring is readily available and simple to repair.

- Hydraulic oil needs to be cooled through a radiator, which sometimes isn’t enough to keep it cool. Inefficiencies with hydraulic hoses mean that the oil doesn’t dissipate the heat along its run, relying solely on hydraulic oil cooler radiator.

Nakayama produce the electric jaw crusher, horizontal impact crusher, vertical shaft impact crusher, cone crusher, and roll crusher. Offered in a range of sizes the future of crushing has arrived.

Give us a call or get in touch if you would like to buy, discuss or have a general enquiry about a material processing, we have a range of machines available. Click here for contact details.